BFSV investigates beverage cans

.

Beverages are available in a wide variety of containers in the German retail trade. In addition to glass and plastic bottles, aluminum and tinplate beverage cans have become indispensable. They can be found in beverages ranging from beer to soft drinks.

At the same time, they have long been caught in a complex conflict of advantages and disadvantages. While the extraction of aluminum requires large amounts of energy, the metal has good recyclability. The body of the can allows for great design versatility, but recycling is energy-intensive. The can has an absolute barrier against oxygen and water vapor, but cans usually hold only very small amounts of liquid.

In focus: What makes the can leak tight?

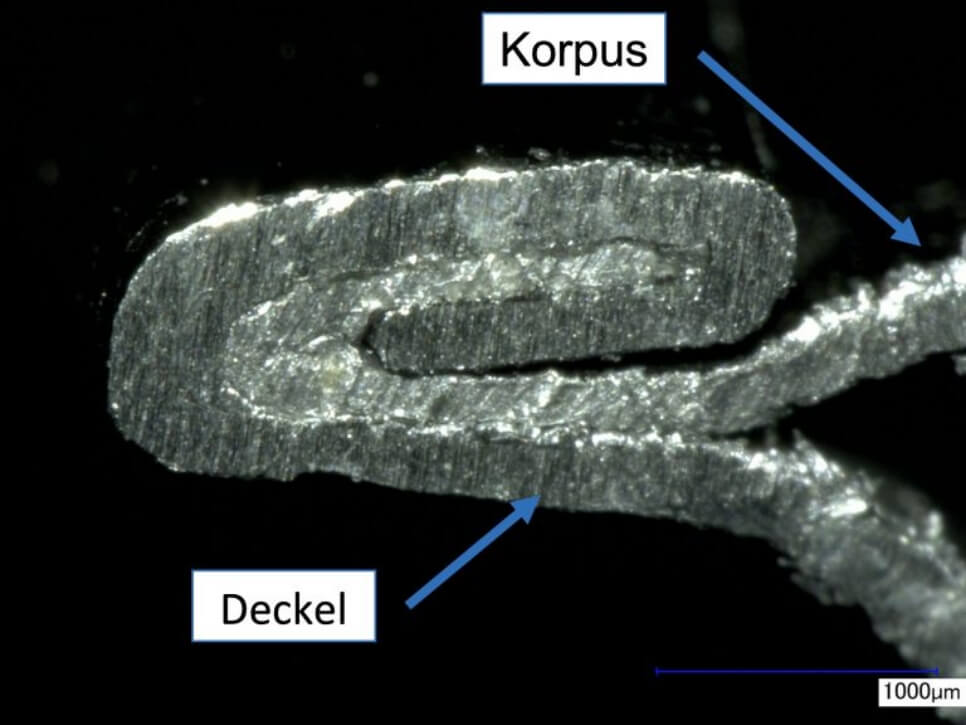

The following microscope images of beverage can crimping were taken in the course of investigations on beverage cans. Here you can clearly see how the metal of the body and the metal of the lid have been deformed into each other. The figure shows a section through the crimping of an aluminum beverage can for soft drinks. The thicknesses of body and lid are in the range of 170-210 µm. The thin plastic seal in the beading area cannot be seen. It has a thickness of only a few µm.

BFSV GmbH inspects packaging of all kinds. Also beverage packaging. You want to ensure that your goods arrive safely at their destination? Talk to us!

Cut through flanging – aluminum beverage can